Metals such as copper and lead which have very limited solubilities in each other are difficult to alloy by conventional means but copper-lead powder mixtures have excellent cold pressing properties. They can be compacted at pressures as low as 11 ksi (76 MPa) to densities as high as 80% and, after sintering, can be repressed at pressures as low as 22 ksi (152 MPa) to produce essentially nonporous bearings.

Copper-lead sintered bearing materials with a lead content of 40-45% have tensile strengths of about 11 ksi (76 MPa), Vickers hardness values of about 32 and a fatigue strength of 3 ksi (21 MPa), which is almost double that of a white metal bearing. The surface properties are good enough to permit use in an automobile engine without an overlay.

Copper-lead alloys containing about 30% lead are stronger but have less satisfactory surface properties and are usually used with a thin lead-tin overlay.

If the copper-lead alloys do not have sufficient load-carrying capacity, the lead content is reduced, and tin is added to improve the strength. Typical is a 74Cu-22Pb-4Sn composite. This material has a tensile strength of 17 ksi (117 MPa) and a Vickers hardness of 50. Its fatigue strength of 5 ksi (34 MPa) is almost three times that of white metal liners. However, an overlay is required, if this alloy is to be used in an automobile engine.

Where still greater strength and hardness are required, an 80Cu-10Pb-10Sn alloy is used. This composition usually has a Vickers hardness of 60-80 but can be cold worked to a hardness as high as Vickers 130. It has a tendency to seize, however, and is normally used with grease rather than oil lubrication.

Steel-backed copper or copper-lead-tin P/M materials are being used in an increasing number of applications to replace solid bronze bearings. They are produced by spreading the powder in a predetermined thickness on a steel strip, sintering, rolling to theoretical density, resintering and annealing. The final product has a residual porosity of about 0.25%. Blanks of suitable size are cut from the bimetallic strip, formed and drilled with oil holes or machined to form suitable grooves. These materials are represented by four groups:

A Cu-25Pb-0.5Sn alloy is used with an overlay plate for high load applications.

A Cu-25Pb-3.5Sn alloy is used widely for such applications as cam bearings, turbine bearings, pump bushings and high speed thrust washers.

A Cu-10Pb-10Sn alloy is used for shock and oscillating loading applications such as piston pin bushings, rocker arm bushings, wear plates and thrust washers.

A Cu-50Pb-1.5Sn alloy is used for intermediate duty applications. 7

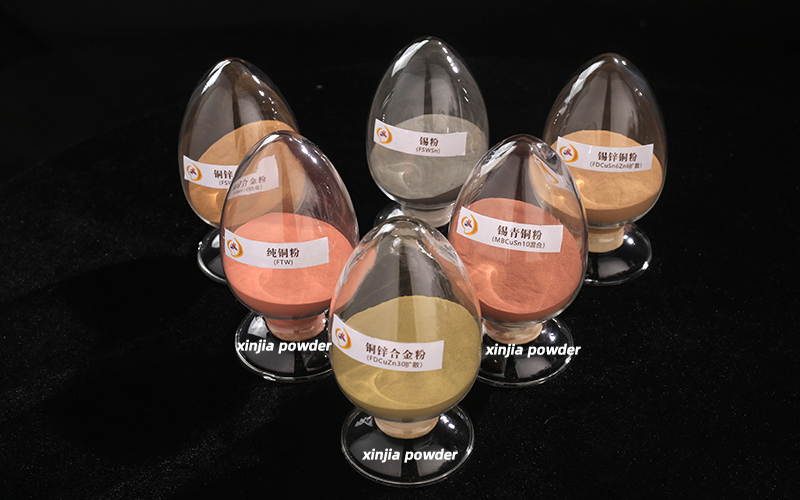

How to find high-quality metal powder production manufacturers?

xinjia copper powder