Copper zinc alloy powder-FSWH10

$12.00

Notice: Due to fluctuations in copper prices, the displayed prices are only historical reference prices. Please contact us for the latest free quotation.

Copper zinc alloy powder-FSWH10

Description

Non Ferrous Powders

Brass Powder-Bronze Powders Supplied By xinjia Metal Powders

We are a specialist supplier of brass powders -Copper zinc alloy powder in a range of particle sizes and shapes which meet specific technical requirements such as Apparent Density and composition. We manufacture brass powders on site here in anhui china and sell large quantities into a wide range of markets and applications around the world.

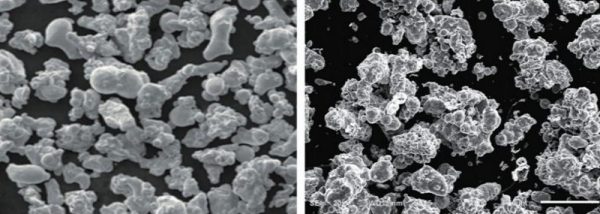

Electron microscope image

Product parameters

|

Type |

Particle |

Particle Size Distribution/% |

TAP Density (g/cm3) |

Flowability of powders (s/50g) |

|||

| ≥150㎛ | 150-75㎛ | 75-45㎛ | ≤45㎛ | ||||

|

FSWH10 |

150㎛ |

≤3 | 20-30 | 30-40 | ≤55 | 2.0-3.5 | ≤45 |

|

75㎛ |

– | ≤3 | 15-35 | ≥65 | 2.0-3.5 | ≤45 | |

|

45㎛ |

– | – | ≤3 | ≥97 | 2.4-3.8 | – | |

|

FSWH20 |

150㎛ |

≤3 | 20-30 | 30-40 | ≤55 | 2.0-3.5 | ≤45 |

|

75㎛ |

– | ≤3 | 15-35 | ≥65 | 2.0-3.5 | ≤45 | |

|

45㎛ |

– | – | ≤3 | ≥97 | 2.4-3.8 | – | |

|

FSWH30 |

150㎛ |

≤3 | 20-30 | 30-40 | ≤55 | 2.0-3.5 | ≤45 |

|

75㎛ |

– | ≤3 | 15-35 | ≥65 | 2.0-3.5 | ≤45 | |

|

45㎛ |

– | – | ≤3 | ≥97 | 2.4-3.8 | – | |

Brass Powders Technical Description

Brass powders are manufactured by water-atomising. In addition, we can offer Dendritic Brass Powders (see “Speciality Powders”) produced via a sinter-diffusion bonding route to give irregular, spherical and dendritic morphologies respectively. Properties and, therefore, uses vary with particle shape / size / surface area, composition and by carefully selecting the correct grade, brass powders find applications in diverse markets and technologies.

Our brass powders are characterised by

Tight chemical control

Low lead (Pb) content

Good sinterability

Highly reproducible batch after batch

Available in a variety of UN-approved packaging options including steel drums (50-100kg) and Big Bags (250, 500, 1000kg).

Brass Metal Powder

Brass metal powders are alloys composed of copper and zinc. It is used in various industries such as electronics because of its extremely low friction coefficient, excellent corrosion resistance, and thermal conductivity. Brass Screening/Sieving As with many metal powders, the density of the powders can cause problems in screening brass powders. Heavy metal powders accumulate on the screen in conventional sieving machines, causing clogging, and sieving efficiency is sometimes reduced.

Physical property

There is a wide variety of sizes distribution, such as granules, powders, strips, and wires.

Chemical properties

Standard alloy represented by Brass Metal & Powder

a) Cu=55%/Zn=45%.

b) Cu=65/Zn=35%.

c) Cu = 70%/Zn = 30%,

d) Cu = 80%/Zn = 20%,

e) Cu=85%/Zn=15%

f) Cu = 90%/Zn = 10

Type of brass Metal

Admiralty brass contains 30% zinc and 1% tin, and it suppresses dezincification in most environments.

Aich’s alloy contains 60.66% copper, 36.58% zinc, 1.02% tin and 1.74% iron. It is excellent in corrosion resistance, hardness, and toughness and is designed for ships. Its unique use is to protect the ship’s bottom, but recently it has become less popular due to the development of cathodic protection. Its appearance resembles gold.

α brass with a zinc content of 35% or less is malleable, can be cold worked, and is used for press and forging. It has a face-centered cubic crystal design and retains only one phase. Prince metal is a type of α brass with 75% copper and 25% zinc. It was used as an imitation of gold because of its beautiful yellow color and was named after Rupert of the Rhine River.

Α-β Brass (Man metal), also called double Brass, contains 35-45% zinc and is suitable for hot processing. αβ brass is usually hot worked.

Specification of Brass Metal Powder

Brass Metal Powders use for Friction materials, gears, wheels, nuts, valves, fasteners, hardware, lock cylinders, latch bolts, automotive kits, military supplies

Powdered Brass has good quality, low acid content, and high purity.

Water Atomized Brass Powder, Pre-alloy Diffusion Brass Powder

The appearance of brass powder: Uniform Color, Gold, Indeterminate

Characteristics of Brass Powder: The Zn content in brass powder greatly influences mechanical properties and workability.

Brass powder also affects electrical conductivity, thermal conductivity, and density. We manufacture brass powder according to customers’ requests, and we can flexibly respond to orders for chemical composition and particle size.

Brass Powder Manufacturing Process: Electrolytic Copper Sheet – Melting – Water Atomization – Drying

Annealing Crash Sieving Blend Packing

Powdered Brass Applications powder metallurgy, friction, anti-friction, diamond tools, brazing, and chemistry

Brass metal powders Conclusion

The fine, high-purity brass powder is used as a raw material for cold casting in casting resins such as polyester, epoxy, and fast-casting polyurethane resins to create the appearance and feel of genuine metal brass. Further, it is added in a considerable amount to a resin mixture and used as a filler to enhance the casting material’s density and thermal conductivity. Cold casting is a term used to describe mixing the metal powder into resin to create castings with a metallic appearance. The stern casting of metals is a fast and much cheaper process than casting molten metals (the lost wax method).

Additional information

| Product name | Copper zinc alloy powder |

|---|---|

| CAS NO. | 7440-50-8 |

| Place of Origin | anhui, China (Mainland) |

| Brand Name | xinjia |

| Particle-size | -40/200mesh or Customized |

| Shape | Powder |

| Color | red |

| Produce method | Water Atomized |

| Purity | 99.6% |

1 review for Copper zinc alloy powder-FSWH10

You must be logged in to post a review.

FAQ

All the goods are inspected before shipment. If the goods can’t come to the quality we promise, you can ask for refund.

Sure. If needed, we can customize those powders for you.

We have our own 30000m² factory in Tongling, which can produce the products required by customers in time and have sufficient production capacity.

We can provide samples to customers and send them to consumers in time by express.

We can provide corresponding customized solutions according to the specific needs of customers.

Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

Generally it is 5~10 days if the goods are in stock.Or it is 45 days if the goods are not in stock, it is according to quantity.

We are factory,Our factory is located in Tongling, with corresponding R&D and production capabilities.

xinjia –

Good quality